- customized and at the same time economic solutions due to the modular design

-

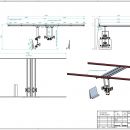

a variety of suspension possibilities

- on existing pillars and girders,

- ceiling beams and plates,

- at consoles or booms or

- on separate pillars

- if needed, calculation and delivery of possibly necessary steel substructures

- a minimum amount of components to simplify installation

- electrical drives for larger crane dimensions and/or higher loads

- on request installation can be carried out by our service team

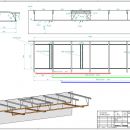

Design and layout of lightweight crans

Each manufacturing setting is different. Only in few cases it is possible that the entire production planning for a new building can be done on a greenfield. More often material flows must be re-arranged as new products are added to the production program or more efficient machines are involved in production.

By planning our WIRTH X-Y lightweight cranes and by creating layout drawings for your specific manufacturing setting we offer optimized solutions for the material flow in your company taking into account the given structural conditions.

Installation of lightweight crane systems

Our qualified technicians that are responsible for lightweight cranes and slewing cranes have longtime experience in installing crane systems.

We always ensure that our technicians are up to date regarding technology and applicable DGUV regulations (German Social Accident Insurance) such as BGV (Occupational Health and Safety Regulations) and UVV (accident prevention regulations). For this reason our technicians take part in trainings of the manufacturers of the cranes we install and seminars of the TÜV (German technical supervisory society).

Our technicians are of course qualified to drive forklifts and to operate work platforms and cranes.

We carry out installations of possibly necessary steel substructures and structure connections as well as electrical, professional and dowel installations.